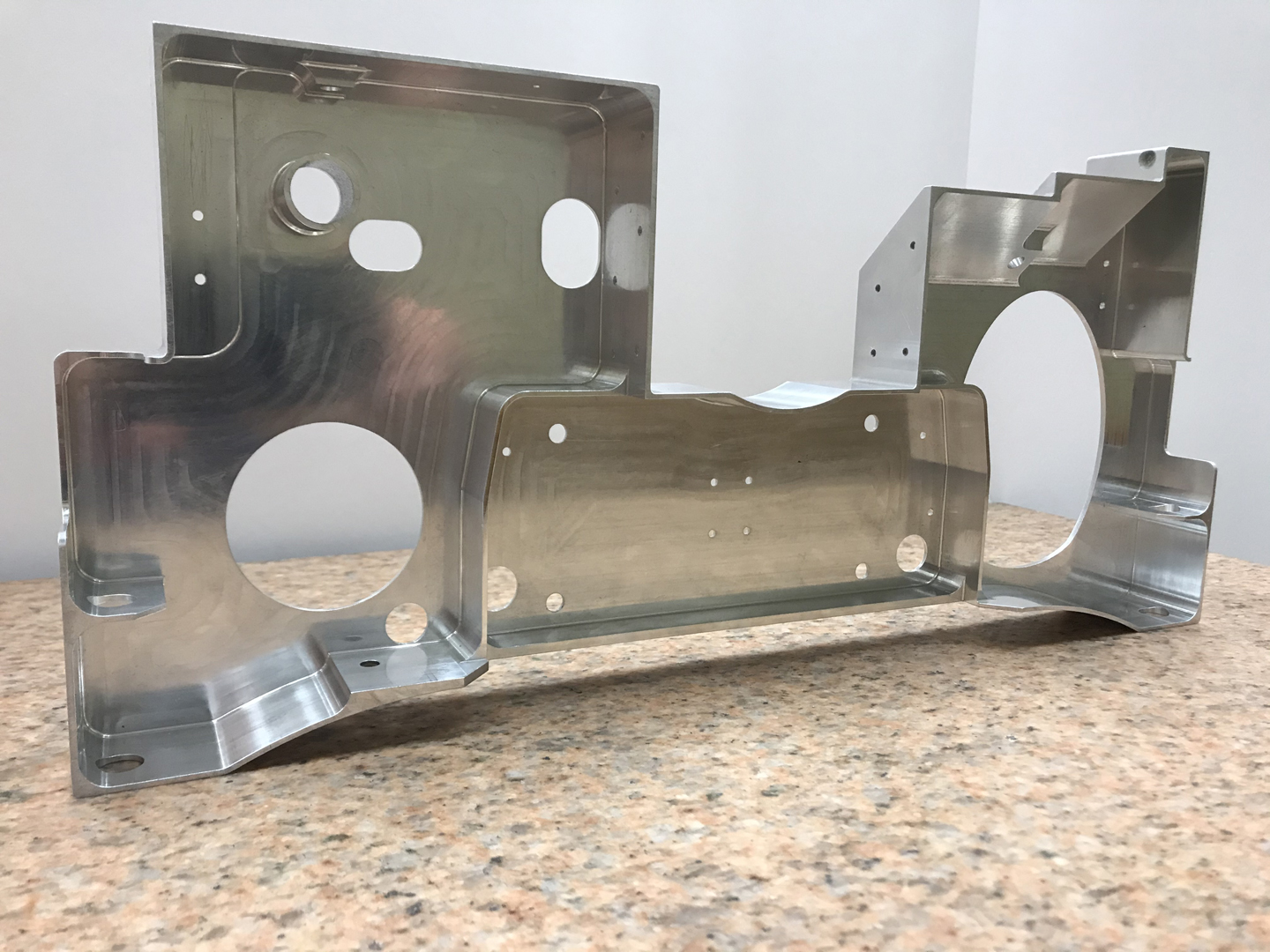

Talbar Tool & Die possesses a very diverse range of skill sets and capabilities. Our tool room is fully staffed with Journeymen toolmakers, each boasting 30 plus years experience in the trade. Our Toolmakers have the ability to conventional mill, grind and edm which give us great flexibility and success in our quick turn capabilities. The combined equipment and personnel in the CNC Milling and Turning departments is able to support prototype thru production level builds at highly competitive pricing. Every job is treated the same whether it be prototype, job shop or production level work. Quality is enforced at every step of the process and no job ships without a fully complete inspection report.